Ford has since 2003 has started using new and modern technologies in its production processes in its facilities in the US. The result of this has been a round about 70% reduction in injuries related to the production line work.

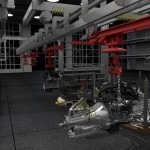

The company has started to use a data based R&D system to help develop tech for use on the production line to help reduce stress and injuries to employees working on the production line. A part of this system is the use of virtual reality, 3D printing systems and full body motion capture.

The full-body motion capture system uses an array of over 52 motion-capture sensors placed on the body of an employee to monitor body movements and evaluate muscle strength and weakness and body imbalance. The immersive virtual reality system uses 23 motion- capture cameras and a head-mounted display to place an employee in a virtual workspace and evaluate task feasibility and proficiency. The third process, the 3D printing system, uses 3D-printed replica parts to help check hand clearances in the assembly process.

The system has been used on over a 100 Ford models to date with the latest being the new Mustang and Explorer SUV.

Source: Autocar India